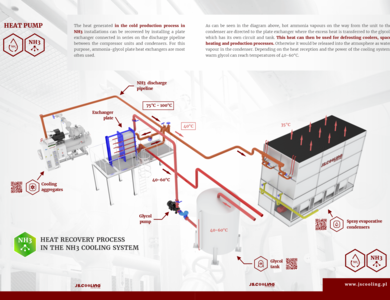

The heat generated in the cold production process in NH3 installations can be recovered by installing a plate exchanger connected in series on the discharge pipeline between the compressor units and condensers. For this purpose, ammonia-glycol plate heat exchangers are most often used.

As can be seen in the diagram above, hot ammonia vapours on the way from the unit to the condenser are directed to the plate exchanger where the excess heat is transferred to the glycol, which has its own circuit and tank. This heat can then be used for defrosting coolers, space heating and production processes. Otherwise it would be released into the atmosphere as water vapour in the condenser. Depending on the heat reception and the power of the cooling system, warm glycol can reach temperatures of 40-60°C.

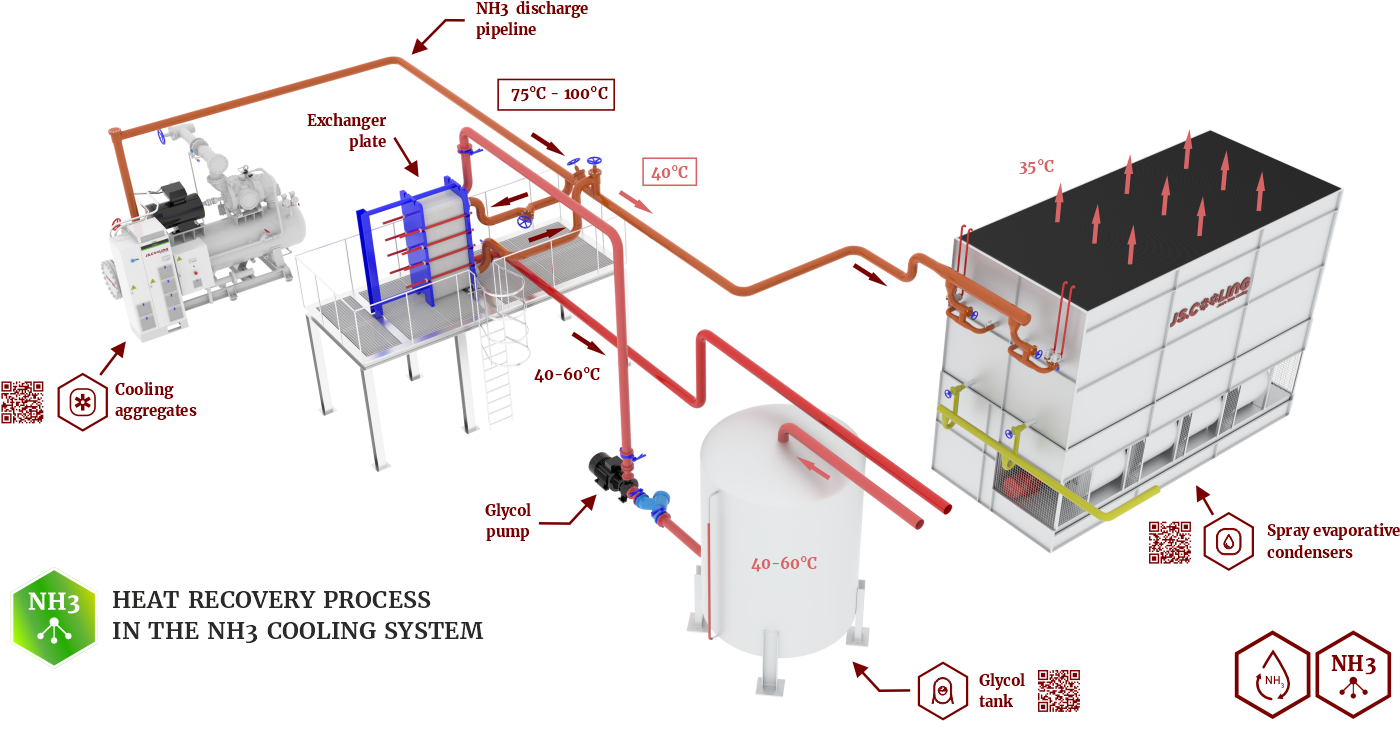

Warm glycol is also an ideal solution for defrosting coolers. Thanks to it, you can replace electric heaters, thus reducing electricity consumption and, consequently, operating costs. By using automatic valves, the defrost takes place at scheduled times and the defrost time of the radiator is shorter compared to electric heaters.

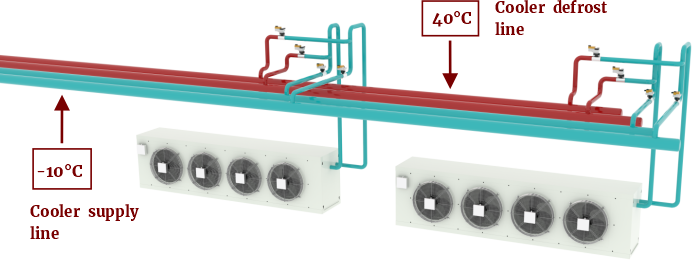

In addition, the heat recovered in the exchanger can heat all kinds of rooms in industrial plants through air handling units thanks to the use of glycol heaters. In most cases, the heat supplied to the units comes from gas combustion, so using the above solution can completely eliminate gas consumption for heating purposes.

By using an additional hot glycol-water exchanger, it is also possible to preheat domestic hot water (DHW) used for production processes.

Comparison of two types of refrigeration installations

| Cooling installation without heat recovery | Cooling installations with heat recovery | |||

| Defrost coolers | Electric heaters | Warm recycled glycol | ||

| Space heating | Gas | Warm glycol fed to the heater | ||

| Domestic hot water | Gas | Initial heating of water through an additional water / glycol exchanger | ||

| Liquefaction | Working performance at high efficiency and spraying efficiency | Reduced condenser time and efficiency | ||

| Energy efficiency and ecology | The excess heat is released into the atmosphere | Recycled heat significantly reduces electricity and gas consumption |

Application + Audit + Documentation

When installing a heat recovery installation, you can count on a return in the form of White Certificates, which can then be sold or kept for investment, because their value is constantly increasing from the moment they appear on the market. The amount of TOE s received depends on the amount of energy saved, which will be demonstrated after the final audit.

As part of the heat recovery contract, we offer assistance in completing all formalities (submitting an application, conducting an audit before and after installing the heat recovery installation).

Files to download

- Catalog Heat pump - JS.Cooling download files