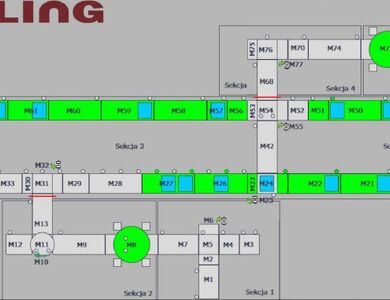

Construction of a cooling tunnel for pallet cooling at SM Mlekpol ZPM Sokółka, consisting of: chain conveyors, roller conveyors, angle transfers, turntables, pallet wrappers, glycol coolers and a flow control system.

Cooling of goods on EURO pallets by blowing cold air from glycol coolers, to which the cold is supplied from a cooling machine manufactured by our company. The movement of the pallets in the tunnel is monitored by flow sensors through a central management system, which is also responsible for controlling the temperature in the tunnel and the speed of the pallet flow.

Transport of pallets inside the tunnel, change of direction of pallets by means of angle transfer, exit of product from the tunnel.

Wrapping of pallets before entering the tunnel, change of direction of pallets via a turntable.